How To Cut Angled Slots In Wood

One of the most popular ways to create a 3 dimensional assembly of waterjet cut parts is via the t-nut technique. In this technique, a bolt or screw is passed through a round hole on the faces of one waterjet cut part, and then through a special slot perpendicular to the cut edge of another piece. The bolt is threaded through a nut which is held in place in a perpendicular slot.

Open the taper jig to set the wood at the correct angle. Keep the wood pressed firmly against the edge of the jig while you do this. Use a tape measure to measure from the jig to the ends of the cut you wish to make. Make sure both points are the same distance from the jig. I need to cut a 3/16' 45 degree angled slot along the length of a 4' by 26' by 3/4 piece of oak. The slot is located approximately 1' in from the long edge and runs the length of that edge. Slot goes all the way from edge to edge, so can be done without a plunge.

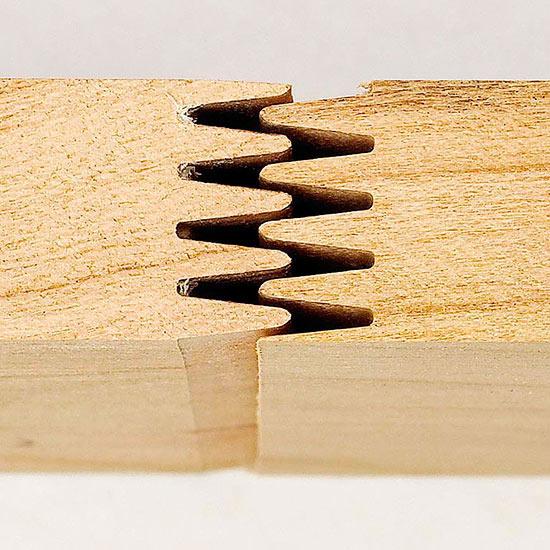

The mating edges of both parts are usually cut with tabs and slots to further secure them together. This is similar to the finger joint or comb joint sometimes found in woodworking.

Illustration : CAD drawing of parts to be joined at their edges with the t-nut technique

Illustration : Waterjet cut pieces joined at the edge with the t-nut technique

Illustration : Another view of the t-nut technique with the same part from the previous photo

The slots cut into the face can be placed along the edge for maximum space savings. For more stability, the slots should be surrounded by solid material. This is analogous to the mortise and tenon joint of woodworking.

Illustration : Parts to be assembled using the t-nut technique;

the slots are placed in a location which provides more stability.

Illustration : The t-slot technique in a more

stable configuration: the slots in the center of the part

Illustration : Another view of the more stable variation of the t-slot technique

How To Cut Angled Slots In Wood Floors

Note that the slot which holds the bolt extends slightly beyond the nut. This is to make sure that the bolt fully engages all the threads on the nut. It also gives some flexibility in the length of the bolt used.

You might need to consider making the tabs slightly smaller than the slots or overcutting the corners in order to compensate for rounded inside corners due to the waterjet's kerf, as shown below. (More information on kerf can be found in our article on the limitations of waterjet cutting).

Illustration : Inside corner reliefs on tab section to compensate for kerf

How To Cut Angled Slots In Wood Dowels

Illustration : Inside corner reliefs on slot section to compensate for kerf

Since the cut edge of the part is used in contact with a flat face, you should consider the use of low-taper waterjet cutting for this type of construction.

You should decide whether it's more important to have a tight fit or easy assembly.

If you go with 'tight fit', you should design the slots slightly undersized (0.005 or so), and fix it by filing away any excess. Heating the hole section with a torch or heat gun so that it expands will make putting the pieces together easier. You can force the pieces together with a press or even a hammer.

If you want 'easy assembly', you can get the parts to hold together more tightly using retaining compound (Loctite makes a good one) or epoxy.

Here is a complete box made using this technique. The box sides have been laser cut from clear acrylic, which lets you see how the whole thing is assembled.

How To Cut Angled Slots In Wood Doors

Illustration : Box assembled with the t-nut technique